Phone:

Phone:

Phone:

Phone:

Shanghai Longsheng Chemical Co., Ltd

Address:4th Floor, Building 2, No. 10, Lane 455, Miaoqiao Road, Pudong New Area, Shanghai

Email:sales@shlschem.com

Phone:021-68249787

To comprehensively enhance the company's safety management level, strengthen employees' emergency response capabilities, and promote a deep understanding of safety production standardization, the company recently successfully held a special training session on "Safety Standardization and Corporate Emergency Management."

This training was delivered by Wang Jing, the company's Safety Responsible Person. Centered around the latest national standard "GB 45673-2025", it systematically explained the essence of safety production standardization, the establishment process, key review points, and emergency management requirements. In-depth analysis was conducted using typical accident cases, providing authoritative guidance and profound warnings for the company's safety production management work.

The training began by clarifying the core definition of safety production standardization: Through the participation of all personnel in the entire process, establish and maintain a safety production management system to achieve systematization of safety and health management, standardization of post-operative behaviors, intrinsic safety of equipment and facilities, and fixed placement of tools in the working environment, with continuous improvement.

Its core objectives can be summarized as the "Four Have" principle:

1. Have Rules to Follow: Establish a comprehensive safety management system and operating procedures to ensure clear standards for every step.

2. Have Designated Responsibility: Implement the safety production responsibility system, detailing responsibilities to specific posts and individuals.

3. Have Evidence for Verification: Maintain complete documentation and operation records, enabling traceability of the management process.

4. Have Supervision: Build a sound supervision system to promptly identify and correct safety management loopholes.

From a practical perspective, safety production standardization covers key actions such as "system establishment, hazard monitoring, hidden danger rectification, and fixed-position operations." For example, the standardized use of workshop management boards and the application of safety (interlock) technologies are important manifestations of standardization implementation.

Establishing safety production standardization is not an overnight task. It requires following the "Plan-Do-Check-Act" (PDCA) cycle and progressing orderly through 8 phases:

1. Planning, Preparation, and Goal Setting:

Establish a leadership team (headed by the primary responsible person of the enterprise, with heads of various functional departments as members) and an execution team (composed of staff from various departments) to clarify organizational support.

Formulate standardization construction goals based on the enterprise's actual situation, decompose responsibilities and tasks, and ensure the implementation of tasks at each stage.

2. Education and Training:

Conduct training by level and category:

Leadership:Promote the importance of standardization construction to unify understanding.

Execution Personnel:Provide professional training to ensure accurate understanding of standard clauses and execution requirements.

Frontline Employees: Conduct specialized training on operating procedures to promote participation by all staff.

3. Current Status Assessment:

Compare against professional assessment standards to survey the safety management status of each department and the condition of on-site equipment and facilities, accurately identifying problems and deficiencies as targeted basis for subsequent rectification.

Adjust compliance goals promptly if the enterprise's scale or process characteristics change.

4. Development and Revision of Management Documents:

The core is ensuring documents' "compliance" and "effectiveness": Based on the assessment standards and problems identified during the status assessment, develop a plan for creating/revising documents. Departments lead the revision of safety management systems, operating procedures, etc., avoiding "emphasizing format over content."

5. Implementation, Operation, and Rectification:

Apply the revised responsibility system, rules, regulations, and operating procedures to daily work.

Conduct real-time checks against standard clauses, identify problems, and promptly rectify and improve to ensure the systems are "effectively implemented."

6. Internal Self-Assessment:

Organize internal assessments by standardization self-assessment personnel to evaluate the effectiveness of standardization construction and identify gaps for improvement.

7. Application for Formal Assessment:

After passing the internal self-assessment, submit an application for external assessment according to the procedure.

8. External Assessment:

A professional organization conducts an external assessment to verify whether the enterprise's standardization construction meets the compliance requirements.Further optimize based on the assessment opinions.

This training focused on interpreting the newly implemented GB 45673-2025 "Basic Requirements and Management Requirements for Safety Production Standardization of Hazardous Chemical Enterprises". This standard has significant adjustments compared to the old version AQ 3013-2008:

1. Expanded Elements: First-level elements increased from 10 to 14; second-level elements increased from 53 to 62. New key modules include "Safety Leadership," "Safety Production Information and Compliance Audit," "Management of Change," and "Emergency Preparedness and Response."

2. Enhanced Focus: Emphasizes "Dual Prevention Mechanism Building," "Asset Integrity," "Chemical Safety and Major Hazard Installation Management," better aligning with the current safety management needs of hazardous chemical enterprises.

3. Updated Second-Level Elements: Among the 62 second-level elements, 23 are retained from the old version, and 39 are new. Enterprises need to focus on adapting systems and processes accordingly.

1. Management of Change (MOC) - Core Link of Risk Control

Management of Change is a crucial barrier for preventing accidents. Any changes in process technology, equipment, facilities, or management must undergo a strict process of application, assessment, approval, implementation, and acceptance.

The core of MOC is safety risk assessment and control. The training warned us through real cases that non-standard changes can lead to severe consequences.

Case Warning: An enterprise failed to conduct a safety risk assessment for a temporary change in a cleaning operation plan, resulting in a fire caused by static electricity. This profoundly illustrates that "small changes" can also trigger "major accidents."

2. Emergency Preparedness and Response - The Last Line of Defense for Protecting Lives

The standard requires enterprises to establish a comprehensive emergency management system.

Organization and Plans: Establish an emergency rescue organization, develop targeted emergency response plans, and regularly review, file, and update them. Key positions require emergency response cards.

Resources and Drills: Equip and maintain emergency supplies and equipment according to standards. Conduct regular emergency training and drills, evaluate their effectiveness, and continuously improve emergency capabilities.

Rescue and Review: Quickly activate the emergency response after an incident occurs. Lessons learned must be summarized afterwards to improve emergency measures.

The training analyzed several typical safety accidents in recent years, including:

The March 11, 2025 explosion accident at Jiangsu Taizhou Huili Biotechnology (caused by illegal trial production).

The March 20, 2025 explosion accident at Henan Xiangcheng Hongqi Biotechnology (illegal production + secondary explosion).

The May 27, 2025 major explosion accident at Shandong Gaomi Youdao Chemical (caused by process defects + substandard raw materials).

Multiple centrifuge accident caused by violation of operating procedures (e.g., flash fires due to failure to introduce nitrogen protection or failure to purge air).

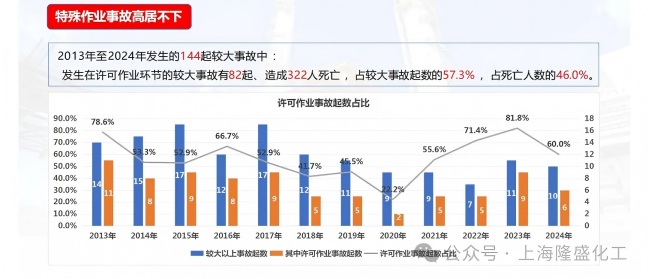

According to accident statistics from 2013-2024 involving 144 major and above accidents, the five categories of problems with the highest proportion are:

1. Special Work Operation Accidents: Accidents during permitted work operations accounted for 57.3% (82 incidents), with fatalities accounting for 46.0%.

2. Contractor Accidents: 34.1% of accidents during permitted work were caused by contractors.

3. Alarm Management Deficiencies: 29.9% of accidents were triggered by improper handling of process alarms or combustible/toxic gas alarms.

4. Violation of Regulations: 68.0% of accidents were directly caused by violations of regulations(87.8% of accidents during permitted work involved violations).

5. Insufficient Personnel Qualifications: 30% of frontline operators have a junior high school education or below, and the proportion of senior skilled workers is only 5% (far below Japan's 40% and Germany's 50%), becoming an important reason for "repeated violations despite repeated checks."

This "Safety Standardization and Corporate Emergency Management" training featured detailed content and profound case studies. It was not only a dissemination of standard knowledge but also a deep awakening of safety awareness.

Safety standardization construction is the cornerstone of the company's stable development, and emergency management capability is key to protecting employees' lives and corporate property.

The company will continue to advance safety production standardization, strictly implement national standard requirements such as GB 45673-2025, continuously improve the safety management system, strengthen risk control and emergency preparedness, and jointly create a safe and reliable working environment, safeguarding the company's sustainable development.

If you wish to learn more about Shanghai Longsheng Chemical's products and updates, please feel free to contact us:

Address: 4th Floor, Building 2, No. 10, Lane 455, Miaoqiao Road, Pudong New Area, Shanghai

Tel: 021-68249787

Email: sales@shlschem.com

WeChat Official Account: 上海隆盛化工

Copyright ©2025- Shanghai Longsheng Chemical Co., Ltd All Rsssts Resved